Are you in the market for a vacuum pump but unsure whether to choose a one-stage or two-stage model? You’re not alone.

This decision can be a bit perplexing, especially with so many options and opinions out there. But don’t worry—by the end of this article, you’ll have a clear understanding of which type suits your needs best. Whether you’re a DIY enthusiast, a professional mechanic, or just someone looking to make an informed purchase, knowing the ins and outs of these pumps can save you time, money, and headaches.

So, let’s dive into what makes one-stage and two-stage vacuum pumps different and discover which one is truly the best for you. Keep reading to find out how your choice can impact performance, efficiency, and even the longevity of your equipment.

Vacuum Pump Basics

Understanding vacuum pump basics is essential before deciding between one stage or two stage pumps. Knowing how these machines operate and the types available helps you choose the right pump for your needs. Let’s break down the fundamentals so you feel confident in your selection.

How Vacuum Pumps Work

Vacuum pumps remove air and gases from a sealed space to create a vacuum. They work by reducing pressure inside a chamber, which causes air molecules to move out. This process allows you to control environments for various applications, from scientific experiments to industrial uses.

Think about inflating a balloon, but in reverse—you’re pulling air out instead of blowing air in. The pump’s internal mechanism creates this suction effect. Some pumps use pistons, others use rotating vanes, but the goal is the same: lower the pressure.

Common Types Of Vacuum Pumps

You’ll find several types of vacuum pumps, each suited for different tasks. The main categories include:

- Rotary Vane Pumps:These are common, reliable, and good for creating medium vacuums.

- Diaphragm Pumps:Ideal for clean or corrosive gases, as they don’t use oil.

- Scroll Pumps:Known for quiet operation and oil-free vacuum production.

- Two-Stage Pumps:These combine two pumping stages to achieve a deeper vacuum than single-stage pumps.

Choosing the right type depends on your specific needs, like the vacuum level required and the type of gases you’re handling. What level of vacuum does your project really demand? Knowing this can save you time and money.

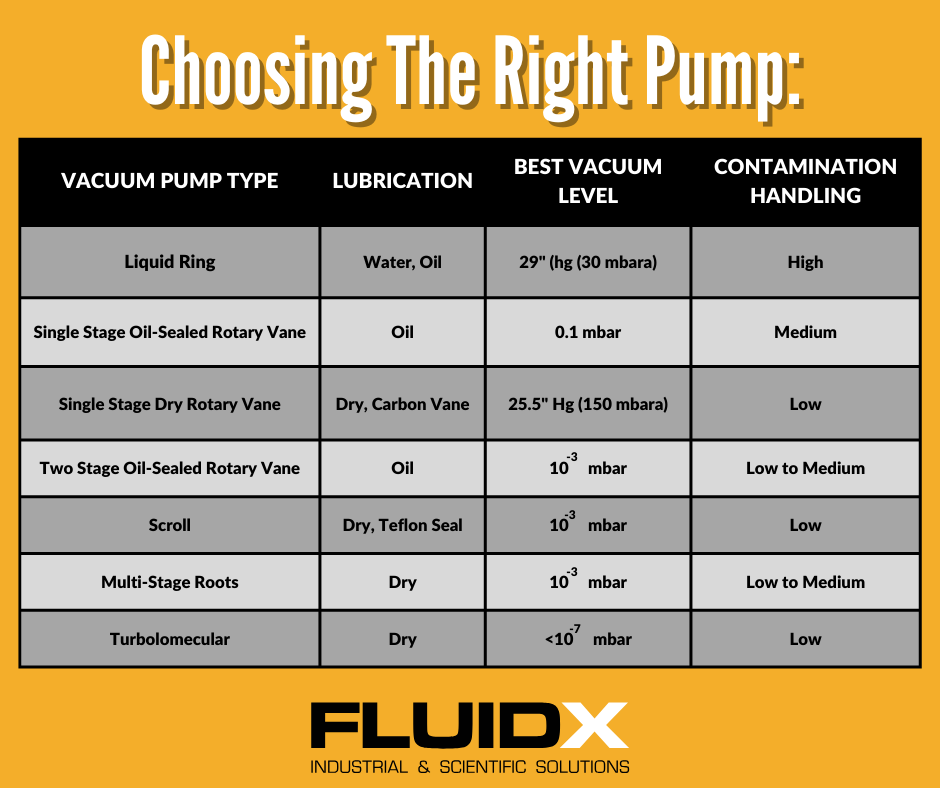

Credit: fluidxinc.com

One Stage Vacuum Pumps

One stage vacuum pumps are a popular choice for many users due to their simplicity and efficiency in certain tasks. Understanding how they work and where they fit best can help you decide if they meet your needs. Let’s break down their design, typical uses, and what you should watch out for.

Design And Operation

One stage vacuum pumps operate with a single compression cycle to remove air and gases from a sealed space. They usually have a straightforward design, with fewer moving parts compared to two stage pumps. This simplicity often means less maintenance and easier repairs.

The pump draws air into the chamber, compresses it once, and then expels it. This process creates a vacuum but generally to a moderate level of pressure. If you need a quick and reliable vacuum without complex mechanisms, one stage pumps might be the right fit.

Typical Applications

One stage vacuum pumps work well in applications where deep vacuum levels are not crucial. They are common in HVAC servicing, laboratory experiments, and simple industrial processes. If you’re working on refrigeration repair or small-scale vacuum packaging, this type of pump usually does the job efficiently.

Think about your project’s vacuum requirements. Do you need a moderate vacuum fast, or is a deeper vacuum necessary? Your answer will guide you in choosing between one stage and more complex pumps.

Advantages And Limitations

- Advantages:They are cost-effective, easy to maintain, and operate with lower noise levels. Their compact design fits well in tight spaces and they consume less power.

- Limitations:One stage pumps can’t reach as low a pressure as two stage pumps. This makes them less suitable for high precision or high vacuum applications.

When I worked on a small refrigeration system, the one stage pump provided a quick vacuum to remove moisture. But for tasks requiring ultra-high vacuum, it fell short, and a two stage pump became necessary. What kind of vacuum level does your work demand?

Two Stage Vacuum Pumps

Two stage vacuum pumps offer a more powerful and efficient solution compared to their one stage counterparts. If you need deeper vacuum levels and better performance, understanding how two stage pumps work can help you make the right choice. Let’s break down their design, where they’re typically used, and what benefits and drawbacks they bring.

Design And Operation

Two stage vacuum pumps have two compression chambers arranged in series. The first stage compresses the gas to an intermediate pressure, and the second stage further compresses it before release. This two-step process allows the pump to reach much lower pressures than a single stage pump.

Because each stage works at a different pressure, the pump runs more smoothly and efficiently. You’ll often find oil or other lubricants used between stages to improve sealing and reduce wear. This design means the pump can handle demanding tasks without overheating or losing power.

Typical Applications

Two stage vacuum pumps are common in industries where a strong, stable vacuum is critical. For example, labs that perform freeze-drying rely on these pumps to create the necessary vacuum level. They’re also widely used in HVAC systems for evacuating air from refrigeration units.

Other uses include vacuum packaging, medical equipment, and even some manufacturing processes like degassing liquids or drying materials. If your work requires a vacuum below 1 Torr, a two stage pump is probably your best bet.

Advantages And Limitations

- Advantages:Two stage pumps can reach much lower pressures, improving process quality and efficiency. They tend to last longer under heavy use due to reduced stress on each stage. Also, they can handle a wider range of gases and contaminants compared to one stage pumps.

- Limitations:These pumps are generally more expensive upfront and need more maintenance. They are bulkier and heavier, which can be a challenge if you need portability. Additionally, the complexity means repairs might take longer and require skilled technicians.

Have you ever struggled with a vacuum pump that just couldn’t keep up? Two stage pumps might solve that problem by delivering steady, reliable vacuum performance. Think about your specific needs and whether a deeper vacuum will actually improve your results before making the investment.

Performance Comparison

Comparing the performance of one stage and two stage vacuum pumps helps you decide which fits your needs best. Each type has strengths that affect how well they perform in different applications. Understanding these differences can save you time and money.

Vacuum Levels Achieved

One stage vacuum pumps typically reach moderate vacuum levels, suitable for many everyday tasks. They are great if you need a decent vacuum quickly without extreme pressure requirements.

Two stage vacuum pumps, on the other hand, achieve much lower pressure, creating a stronger vacuum. This makes them ideal when you need higher precision or work with sensitive equipment.

Have you considered how deep a vacuum your project really needs? Choosing the right vacuum level can improve efficiency and protect your tools.

Pumping Speed And Efficiency

One stage pumps generally pump faster at higher pressures but slow down as the vacuum level increases. They work well for quick jobs or where speed matters more than ultimate vacuum depth.

Two stage pumps maintain better speed across a wider range of pressures, thanks to their second compression stage. This means they handle tougher jobs without losing much efficiency.

Think about whether you need consistent pumping speed or just a quick start. This affects how long your tasks will take and the wear on your pump.

Energy Consumption

One stage pumps often consume less energy during short or light tasks, making them more economical for basic use. Their simpler design means less power is drawn when deep vacuum isn’t necessary.

Two stage pumps may use more energy overall but deliver better performance for demanding jobs. Their efficiency at lower pressures can reduce run time, balancing out higher power use.

Ask yourself if energy cost or performance is more important for your work. Sometimes spending a bit more power saves time and improves results.

Maintenance And Durability

Maintenance and durability play a crucial role in deciding between one stage and two stage vacuum pumps. How often you service your pump and how long it lasts directly impact your productivity and costs. Understanding these aspects helps you choose a pump that fits your needs without unexpected downtime or frequent repairs.

Service Requirements

One stage vacuum pumps usually need less frequent servicing because of their simpler design. However, this doesn’t mean you can ignore regular checks. Oil changes, filter replacements, and cleaning are essential to keep the pump running smoothly.

Two stage pumps require more attention due to their complex structure. You might need to replace seals and gaskets more often, and monitor oil quality closely. If you skip maintenance, performance drops quickly, affecting your operations.

Ask yourself: How much time can you realistically dedicate to pump maintenance each month? Your answer might steer you toward a simpler or more advanced system.

Common Issues

With one stage pumps, common problems include overheating and oil contamination. These issues arise mostly from neglecting routine maintenance or running the pump continuously without breaks.

Two stage pumps face similar issues but also struggle with additional wear on moving parts because of the extra compression stage. This can cause leaks or reduced vacuum efficiency if not addressed promptly.

Spotting early signs like unusual noise or reduced suction power can save you from costly repairs. Do you regularly inspect your pump for these warning signals?

Lifespan Expectations

One stage pumps generally have a shorter lifespan, around 3 to 5 years under moderate use. Their simpler build means fewer parts can break, but they don’t handle heavy workloads as well.

Two stage pumps often last longer, sometimes up to 7 to 10 years, especially when well maintained. Their design handles tougher tasks better, so they wear down slower despite needing more upkeep.

Think about your long-term needs: Are you looking for a pump that lasts many years with steady use, or one that meets basic demands with less fuss? Your choice affects both performance and budget over time.

Credit: www.vevor.ca

Cost Considerations

Cost plays a big role in choosing between one stage and two stage vacuum pumps. Understanding the financial impact helps make a smart choice. This section breaks down key cost factors to consider.

Initial Investment

One stage vacuum pumps usually cost less to buy. They have simpler designs and fewer parts. Two stage pumps require a bigger upfront payment. Their complex build and extra components raise the price. Budget limits often affect this choice.

Operating Costs

Energy use matters for running expenses. Two stage pumps often use more power because they work harder. One stage pumps may be cheaper to run but might not handle tough jobs well. Maintenance costs can be higher for two stage pumps. More parts mean more chances for repairs.

Long-term Value

Two stage pumps last longer in demanding tasks. They keep steady pressure and perform better over time. One stage pumps might wear out faster under heavy use. This affects replacement frequency and overall spending. Think about how long the pump will serve before buying.

Choosing The Right Pump

Choosing the right vacuum pump is more than just picking between one stage or two stage models. It’s about understanding your specific needs and how the pump’s features align with them. Getting this choice right saves you time, money, and frustration down the line.

Matching Pump To Application

Think about what you need the pump for. Different tasks demand different vacuum levels and flow rates. A one stage pump might work perfectly for simple applications like vacuum packaging, while a two stage pump offers deeper vacuum suitable for scientific or industrial use.

Consider the materials you’re handling too. Some pumps handle moisture or corrosive gases better than others. Matching the pump’s capability to your application ensures you avoid damage and maintain efficiency.

Environmental Factors

Your pump’s surroundings impact its performance and lifespan. Is your workspace dusty, humid, or temperature-variable? These conditions affect wear and tear.

For example, a two stage pump with better sealing can resist contaminants in harsher environments. You might also need to think about noise levels if the pump will run near your workspace.

Future Scalability

Ask yourself if your vacuum needs might grow. Buying a pump that just meets today’s demands might limit your options tomorrow.

Two stage pumps often handle increased workload better and maintain vacuum quality over time. Investing in scalability means your equipment can adapt without costly upgrades or replacements.

What’s your plan for growth? Choosing a pump with that in mind can provide peace of mind and protect your investment.

Credit: www.vevor.ca

Frequently Asked Questions

What Is The Main Difference Between One Stage And Two Stage Vacuum Pumps?

One stage pumps compress air in a single step, while two stage pumps use two compression steps. This results in higher vacuum levels and efficiency for two stage pumps.

Which Vacuum Pump Type Is Better For Industrial Use?

Two stage vacuum pumps are generally better for industrial tasks. They provide deeper vacuum levels and handle continuous operation more effectively than one stage pumps.

Are One Stage Vacuum Pumps Suitable For Light Applications?

Yes, one stage pumps are ideal for light-duty tasks. They are simpler, cost-effective, and perfect for applications requiring moderate vacuum levels.

How Does The Cost Compare Between One And Two Stage Pumps?

One stage pumps are typically less expensive upfront. Two stage pumps cost more but offer better performance and long-term energy savings.

Conclusion

Choosing between one-stage and two-stage vacuum pumps depends on your needs. One-stage pumps work well for simple tasks with low vacuum demands. Two-stage pumps offer deeper vacuum and better performance for tougher jobs. Consider the level of vacuum and your budget carefully.

Each type has clear benefits. Think about how often and how hard you will use the pump. This helps you pick the right one without overspending. The best pump matches your specific work and saves time. Simple, clear choices lead to better results.