Have you ever wondered how the invisible force of a vacuum is measured? It might sound like something only scientists or engineers need to know, but understanding vacuum measurements can be surprisingly useful for you, too.

Whether you’re an avid DIY enthusiast, a curious mind, or simply someone who wants to make informed decisions about household appliances, getting a grip on this topic is easier than you think. Imagine having the power to choose the best vacuum cleaner for your home or understanding why certain foods stay fresh longer in vacuum-sealed bags.

Intriguing, right? Let’s dive into the fascinating world of vacuum measurement and uncover the secrets that can make your everyday life a little bit smarter.

Credit: info.teledyne-hi.com

Basics Of Vacuum Measurement

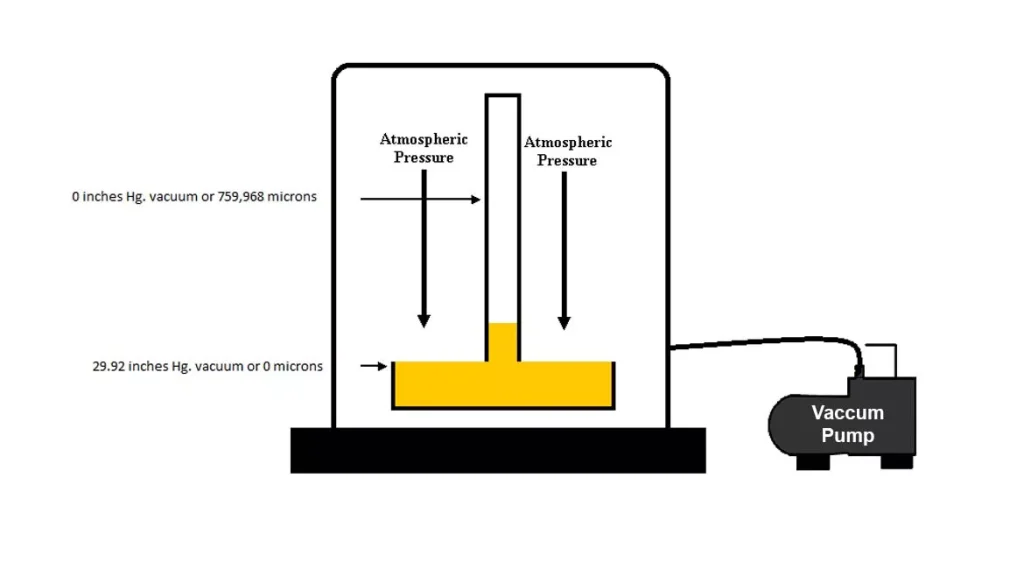

Understanding vacuum measurement is key to many scientific and industrial processes. It helps to know how much air or gas pressure is reduced in a space. This basic knowledge ensures accurate readings and proper equipment use. Vacuum measurement involves comparing pressure inside a system to normal atmospheric pressure. It requires clear units and terms for easy communication and operation.

What Is Vacuum Pressure

Vacuum pressure is the pressure lower than the normal atmosphere. It shows how much air or gas is removed from a space. The lower the pressure, the stronger the vacuum. It is not just empty space but a reduced pressure area. Vacuum pressure is measured relative to atmospheric pressure or absolute zero pressure.

There are two main types of vacuum pressure:

- Gauge Vacuum: Pressure measured below atmospheric pressure.

- Absolute Vacuum: Pressure measured from zero pressure (perfect vacuum).

Units Of Measurement

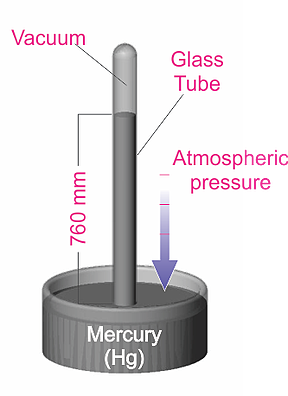

Several units measure vacuum pressure, depending on the application. Knowing units helps to read and compare vacuum levels correctly. Common units include:

- Torr:Based on millimeters of mercury (mmHg), often used in labs.

- Pascal (Pa):The SI unit of pressure, standard in science and industry.

- Bar:Used for higher pressure ranges, one bar equals atmospheric pressure.

- Inches of Mercury (inHg):Common in the US for vacuum and weather pressure.

- Atmospheres (atm):Compares vacuum pressure to normal atmosphere.

Each unit has a specific range and use. Choosing the right unit avoids confusion and ensures accuracy.

Common Vacuum Measurement Techniques

Vacuum measurement techniques help us understand pressure levels inside a vacuum system. Different tools measure various pressure ranges. Choosing the right technique depends on the vacuum level needed and the application.

Mechanical Gauges

Mechanical gauges use physical parts to measure pressure. They often have a spring or diaphragm that moves with pressure changes. These gauges work well for low to medium vacuum ranges. They are simple and reliable, making them common in many industries.

Thermal Conductivity Gauges

Thermal conductivity gauges measure vacuum by sensing heat loss from a heated wire. The wire cools down faster in higher pressure environments. These gauges are good for medium and high vacuum ranges. They provide quick and accurate readings for many vacuum processes.

Ionization Gauges

Ionization gauges measure very low pressures in high vacuum systems. They work by ionizing gas molecules and measuring the resulting current. These gauges are sensitive and can detect extremely low pressures. They are essential in scientific and industrial vacuum applications.

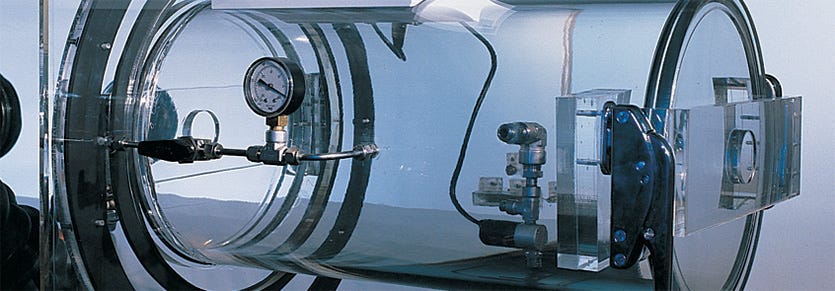

Popular Tools For Vacuum Measurement

Measuring vacuum accurately is essential in many industries, from manufacturing to scientific research. The tools you choose can directly affect the precision and reliability of your readings. Understanding the popular tools for vacuum measurement helps you select the right device for your specific needs and challenges.

Bourdon Tube Gauges

Bourdon tube gauges are one of the most common tools for measuring vacuum pressure. They work by using a curved tube that straightens when vacuum pressure changes, moving a needle on the dial.

These gauges are easy to use and durable, making them great for general industrial applications. However, they usually measure only moderate vacuum levels, so they might not be suitable for ultra-high vacuum tasks.

Pirani Gauges

Pirani gauges measure vacuum by detecting changes in thermal conductivity of gas inside the chamber. A heated wire inside the gauge cools down as the pressure changes, altering the electrical resistance and giving a pressure reading.

This tool is sensitive to low vacuum ranges and often used in processes where you need to monitor vacuum in real-time. Have you ever wondered how small temperature changes can tell you so much about pressure? That’s the magic of Pirani gauges.

Penning Gauges

Penning gauges use ionization to measure very low pressures in high and ultra-high vacuum systems. They create a plasma inside the vacuum, and the current generated correlates with the pressure level.

These gauges provide reliable readings in extreme vacuum conditions and are widely used in scientific research and semiconductor industries. If your work demands precise measurement at near-perfect vacuum, a Penning gauge might be your best choice.

Credit: www.welchvacuum.com

Choosing The Right Method

Choosing the right method to measure vacuum is crucial for getting accurate and reliable results. Not every technique fits every situation, so understanding your specific needs helps you pick the best tool. Think about what you want to achieve and the conditions under which you’ll be measuring.

Application Requirements

Start by considering the purpose of your vacuum measurement. Are you monitoring a simple system, or do you need detailed data for complex equipment? Some methods work better for high vacuum ranges, while others suit low or medium vacuum levels.

Also, think about how often you need to measure. Continuous monitoring demands robust instruments, while occasional checks might allow simpler devices. Your choice depends on whether you prioritize ease of use, cost, or precision.

Accuracy And Range

Accuracy is key when measuring vacuum. Some gauges offer precise readings but only within a narrow range. Others provide a broader range but with less exact numbers.

Ask yourself: How critical is the accuracy for your task? If you’re working in a lab setting, small deviations can matter a lot. But for industrial processes, approximate values might suffice.

- Use ionization gauges for ultra-high vacuum with high accuracy.

- Thermocouple gauges work well for low to medium vacuum.

- Mechanical gauges are durable but less precise.

Environmental Considerations

Your environment impacts the choice too. Dust, humidity, and temperature can affect gauge performance. For example, a sensor exposed to moisture might give faulty readings or degrade faster.

Think about where the gauge will be placed. Will it face vibration, chemical exposure, or extreme temperatures? Picking a method that suits these conditions prevents frequent maintenance and errors.

Have you checked if your measurement setup requires explosion-proof or corrosion-resistant equipment? These factors are often overlooked but vital for safety and durability.

Calibration And Maintenance Tips

Proper calibration and maintenance keep vacuum measurement tools accurate and reliable. Neglecting these tasks can cause errors and reduce the lifespan of your equipment. Regular attention ensures consistent readings and smooth operation over time.

Regular Calibration

Calibrate vacuum gauges at set intervals to maintain accuracy. Use certified reference standards for best results. Keep records of calibration dates and results for future reference. Calibration frequency depends on usage and manufacturer recommendations.

Handling And Storage

Handle vacuum equipment gently to avoid damage. Store devices in clean, dry places away from extreme temperatures. Protect gauges from dust and moisture using covers or cases. Avoid dropping or bumping instruments during transport.

Troubleshooting Common Issues

- Check for leaks if readings are unstable or low.

- Clean sensor surfaces regularly to prevent buildup.

- Replace worn or damaged parts promptly.

- Verify electrical connections are secure and free of corrosion.

- Consult the user manual for specific error codes and fixes.

Credit: www.terrauniversal.com

Frequently Asked Questions

What Units Are Used To Measure Vacuum Pressure?

Vacuum pressure is commonly measured in torr, pascal, and inches of mercury (inHg). Torr is based on millimeters of mercury. Pascal is the SI unit for pressure. Inches of mercury are often used in older systems and automotive applications.

How Do Vacuum Gauges Measure Vacuum Levels?

Vacuum gauges detect vacuum by measuring pressure difference. Mechanical gauges use a diaphragm or Bourdon tube. Electronic gauges employ sensors like Pirani or capacitance types. They convert pressure into readable values on a scale or digital display.

What Is The Difference Between Absolute And Gauge Vacuum?

Absolute vacuum measures pressure relative to perfect vacuum (zero pressure). Gauge vacuum measures pressure relative to atmospheric pressure. Absolute vacuum is always lower or zero. Gauge vacuum can be positive or negative depending on the system.

Why Is Accurate Vacuum Measurement Important?

Accurate vacuum measurement ensures proper system performance and safety. It helps monitor leaks, maintain process control, and optimize energy use. Inaccurate readings can cause equipment damage or product defects. Reliable measurement is critical in industries like manufacturing and research.

Conclusion

Measuring vacuum helps us understand pressure levels clearly. Different tools like gauges and sensors show how much air is removed. Knowing vacuum levels is important for many machines and science work. Precise measurement keeps systems safe and working well. Using the right method makes the job easier and results accurate.

Keep learning about vacuum measurement to handle tasks confidently. It’s simple once you know the basics and tools. Practice and care lead to better results every time.